HTS/Amptek® Industrial Self-Regulating Trace Heating Cable

Industrial trace heating cables, also known as heat tracing cables, are specialized electrical cables used in various industrial applications to maintain the temperature of pipes, vessels, tanks, and other equipment. They are designed to provide controlled and consistent heat to prevent freezing, maintain process temperatures, or facilitate viscosity control of fluids in industrial processes.

Trace heating cables are typically made of a heating element, configured in a weather proof, spooled wire or cable format. This convenient format enables quick and easy installation. The heating element is usually made of resistive alloy materials, such as nichrome, copper in constant wattage alloys, or self-regulating polymers, which generate heat when an electric current passes through them. The insulating layer provides dielectric strength while directing the heat towards the desired location. The outer protective layer provides mechanical protection and resistance to environmental factors.

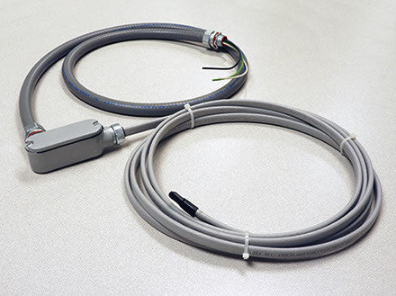

HTS/Amptek® industrial trace heating cables are self-regulating, and are offered in prefinished lengths to make them the most convenient of the available varieties. The most common are self-regulating, constant wattage cable and tape, and mineral-insulated cables. Each design has its own unique properties and applications. Constant wattage cables provide a consistent heat output along the entire length of the cable, making them suitable for maintaining high temperatures in long runs of pipes or vessels. Self-regulating cables, on the other hand, adjust their heat output based on the ambient temperature, making them more energy-efficient and suitable for freeze protection applications, or where temperature control is critical. Mineral-insulated cables which are normally the most difficult to apply, are highly durable and suitable for harsh environments, such as corrosive or high-temperature environments. (See HTS/Amptek Tek-Rod® for preconfigured M.I. cables)

Industrial trace heating cables are used in a wide range of industries, including oil and gas, petrochemicals, food processing, pharmaceuticals, power generation, and many others. Common applications include freeze protection, process temperature maintenance, viscosity control of fluids, and protection against condensation or crystallization in pipes, tanks, valves, and other industrial equipment. For shorter runs and laboratory applications, Heating Tape is an excellent way to apply heat with standard, preconfigured lengths for all common voltages. (See heatingtapes.com for HTS/Amptek Duo-Tape®)

Proper installation and design of trace heating systems are essential to ensure efficient and safe operation. It is important to follow industry standards and guidelines, as well as consult with qualified professionals to determine the appropriate type, size, and configuration of trace heating cables for a specific application. Regular maintenance and monitoring are also necessary to ensure optimal performance and prevent potential issues to keep your system running.